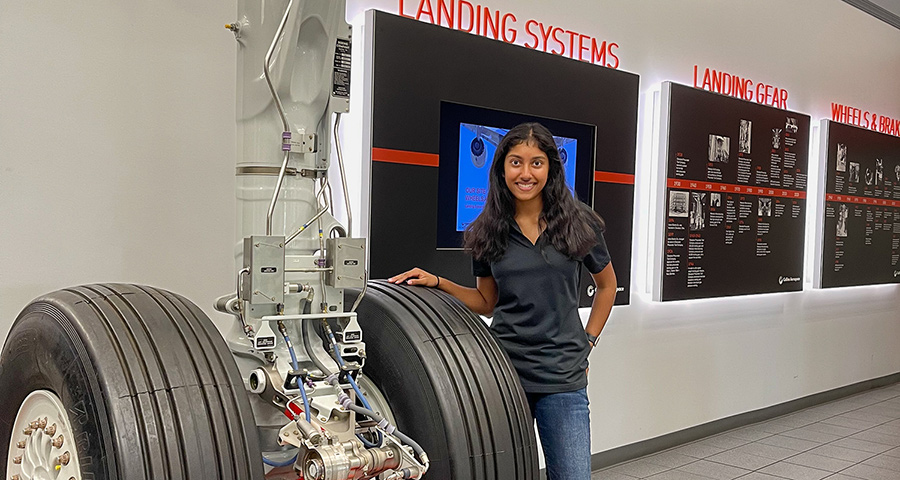

Kasthuri Pillapalayam got the opportunity to work at Collins Aerospace as a manufacturing engineer ntern in summer 2022. She worked at their Troy, Ohio, site, which manufactures wheels and brakes for many commercial and military clients.

My main project this past summer has been to work on process maps and develop standard work for our chemical lines. I collaborated with a lot of the engineers that installed our equipment, operators that had been working the chemical lines for years, and also with our EHS analysts to develop our standard work. I also assisted in the process improvement of our wastewater treatment by providing suggestions for preventative maintenance.

Having learned about standard work, process maps, and preventative maintenance in my industrial engineering classes, this internship showed me the importance of its real-world implementation, and gave so much more meaning to what I study in school.

This internship has been an amazing opportunity to learn more about the aerospace industry, especially the six different business units part of Collins. We were able to listen to and ask questions to executives in avionics, interiors, power & controls, and advanced structures every week.

Additionally, I was able to network with individuals in continuous improvement, shipping, procurement, quality, engineering management, materials, and many other departments. This gave me the ability to identify what full-time roles I might be interested in after graduation.

After having an amazing internship experience, I highly recommend any current engineering students to apply for an internship or co-op. And be sure you visit the Engineering Professional Practice Office. It truly adds another dimension of value to your education!