Student Spotlight: Autumn Cox

Chemical engineering major and business administration minor Autumn Cox spent all of 2022 completing an internship with Malibu Boats.

Chemical engineering major and business administration minor Autumn Cox spent all of 2022 completing an internship with Malibu Boats.

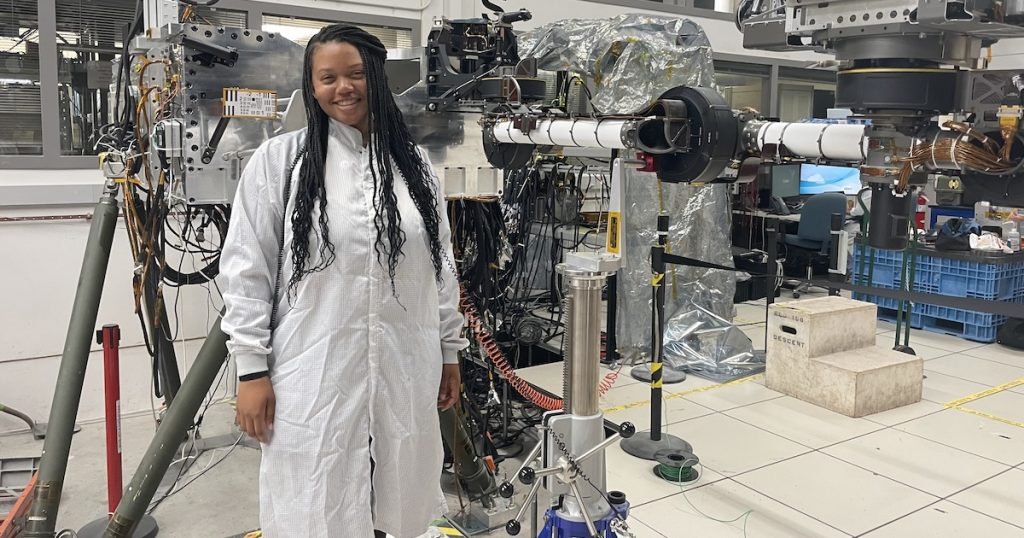

The summer of 2023, undergraduate senior in aerospace engineering Amber Hiscock participated in an internship with Naval Air Systems Command.

Junior in aerospace engineering William Haupt spent the summer of 2023 working for Southern Champion Tray to learn about manufacturing.

My name is Kayla Stevenson. I’m an undergraduate junior pursuing a Bachelor of Science in Applied Artificial Intelligence. Last year, […]

I am Thomas Scott, an undergraduate senior pursuing a degree in mechanical engineering. During my time at Lawrence Livermore National […]

My name is Ian Tulk, and I am a senior studying aerospace engineering minoring in mechanical. Recently, I took a […]

MABE student Christopher Schenck completed a valuable co-op assignment, working for the largest logistics company in the world, the United Parcel Service.

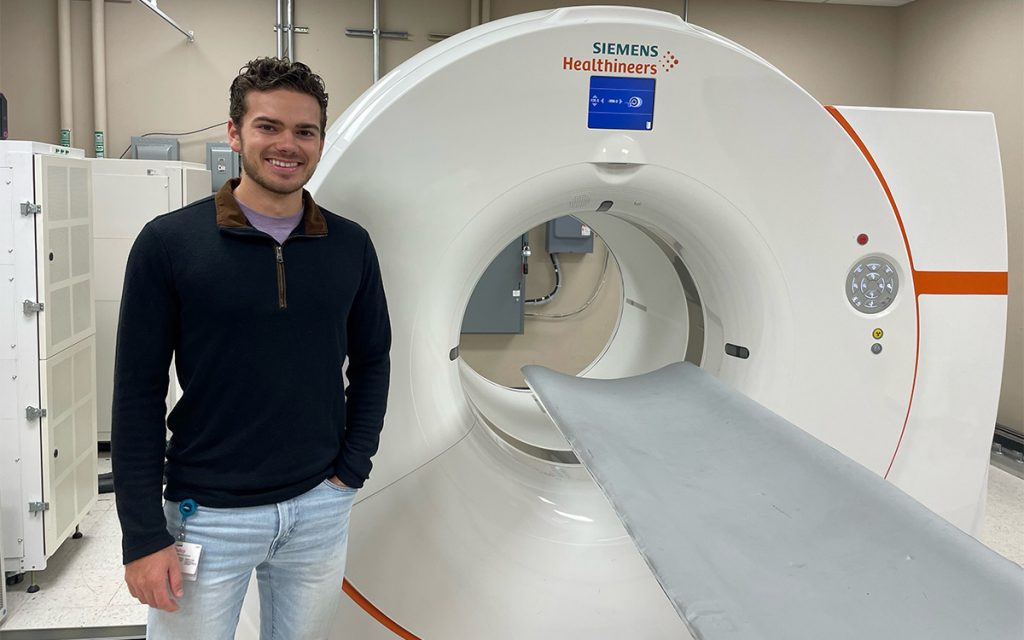

Mechanical engineering junior Camden Shuman gained valuable experience while participating in a coop work program with Siemans Healthineers.

Eli Callendar, a mechanical engineering senior, discusses the skills and processes he learned while participating in a summer internship at Nissan.

MABE senior Zachary Koller learned and applied industry relevant skills during his co-op experience with Beehive Industries in Knoxville, TN.

The flagship campus of the University of Tennessee System and partner in the Tennessee Transfer Pathway.

View our Privacy Policy.